Intralogistic line

The constant evolution of the market has led us to study and design new systems for the transport of goods within the production areas, based on the concept of lean production, a production method aimed at optimizing production processes and increasing the value of products by minimizing waste.

The automation of the logistics chain leads to cost reductions and efficiency gains, as all stages of the production chain (order management - workflow - shipping of the final product - waste disposal) are included, resulting in a very smooth and streamlined workflow.

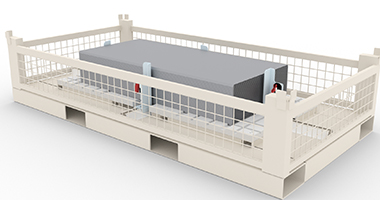

The speed and flexibility in providing the orders for the required goods in the special containers and guided trolleys with hook system, handled by the forklift, guarantee a better efficiency of the production system by optimizing the work cycles, so that the material can be optimally transported to and from the workstations and the use of forklifts can be definitely avoided.

Our products for internal handling with the "towing system" are all certified with the CE mark, which distinguishes them for their manufacturing quality and safety when used in various business sectors.

PROFITABILITY

PROFITABILITY

- Inventory costs reduction

- Downtime decrease

- More competitiveness and company profit

TIME SAVING

TIME SAVING

- Quicker production line supply

- Labour cost saving

- Organized waste disposal

PRODUCTIVITY

PRODUCTIVITY

- Material handling optimization

- Production efficiency increased

- Fast empty return

Product line:

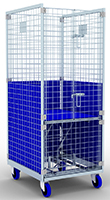

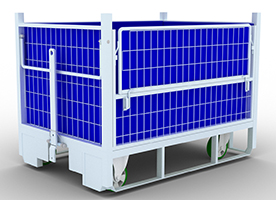

Practical and versatile containers which can be adapted to any kind of processing, equipped with towing system making order picking-delivery-return quicker; this allows a more efficient order handling.

This new kind of products enables an increase in manual handling efficiency, easy and safe order-picking, less product damages, drastically cutting off the cost of inventory, internal logistics handling and in-house transportation.

We produce both standard and customized items, properly designed for any kind of industrial environment, according to any particular needs.

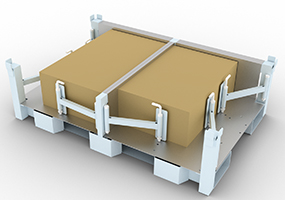

Trolley rack, with roller table: trolleys which are tailored according to specific customer needs. They are practical and versatile, so that they are employed for order moving within work-stations.

PRACTICAL AND MULTIPURPOSE TROLLEYS, ESPECIALLY ADAPTABLE TO MANY APPLICATIONS.

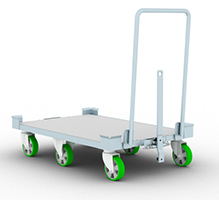

Wheeled platforms with metal plate basement, particularly created to move items on wooden euro-pallets; we design both standard and custom-made platforms.

Easy to be handled, they are equipped with a practical handle and wheels which are suitable for in-house transportation, helping trolley initial boost.

Tailored dimensions according to specific requests:

Dolly platforms: 600*400 mm metal – plate wheeled platforms, suitable for plastic trays and crates transportation.

Also available with customized dimensions.

Platforms are employed within many industry environments: automotive, food and logistics, thanks to its practical dimensions.

To help automatized transportation, dolly platforms can be towed thanks to the “tugger-train” system; but they can also be moved manually.

Every day we study and project space-saving, ergonomic trolleys and containers, aiming at safety engineering and security on workplace; the grip handle perfectly fits standard safety measures and the sprung base enables the staff to load and unload items comfortably and safely.

Retailers over the world are in a race to adapt their supply chain to these more frequent and diverse deliveries, while maintaining the efficiency in supplying their production line.

A more efficient internal logistics can enable a reduction in handling costs, a space optimization and shorter delivery times.

We, Picchi snc offer a wide range of carts and containers which aim at improving material handling.

Our customers’ needs and demand have always been our main priority; for this reason, our project Engineering unit rigorously co-works with the client to succeed in designing and creating new solutions which perfectly fit the customer needs.

Suitable for waste disposal and carton boxes storage within storerooms.

Thanks to the innovating Tugger-Train System, all production cycles are efficiently optimized; goods can be easily moved improving the in-house logistics.

SAFETY

SAFETY